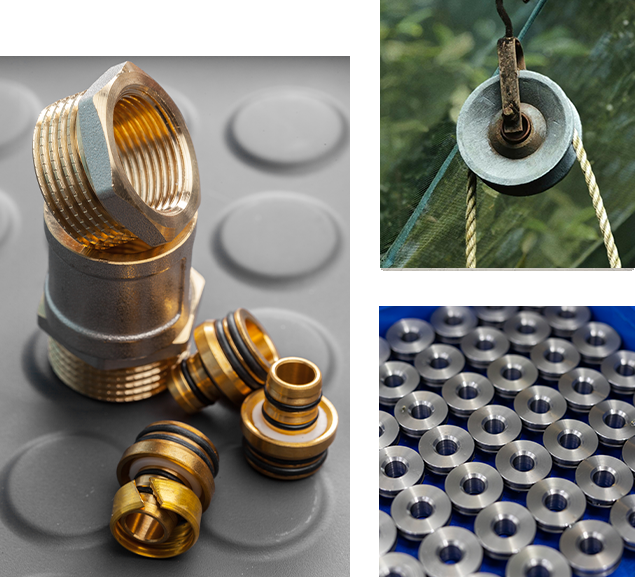

Our Infrastructure

Our robust and well-integrated infrastructure is the backbone of our manufacturing excellence. Designed to support high-precision production and large-scale output, our facility is equipped with advanced technology and optimized workflows that ensure efficiency, consistency, and quality.

- Modern Manufacturing Facility

- Advanced CNC Machinery

- Precision Component Production

- Quality Control Lab

- Power & Connectivity